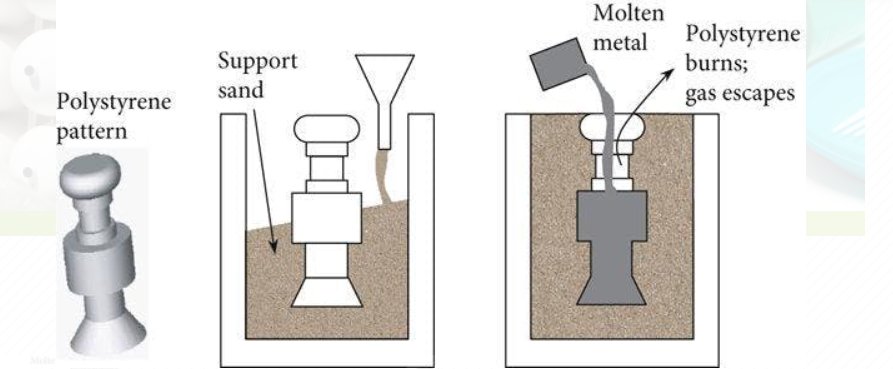

Lost-foam casting is a unique technique in the field of metal casting. This creative approach produces intricate metal components using a foam design that evaporates as molten metal is put into the mold. The procedure is essential for creating elaborate and sophisticated designs that could be difficult to cast using conventional techniques.

Lost-foam casting, also known as evaporative casting, is a sophisticated technique for crafting intricate metal components. This procedure makes use of an expanded polystyrene (EPS) foam mold. The foam pattern may be cut from a foam block, carved, or produced using a process akin to injection molding. The foam mold is then given a ceramic refractory covering to isolate it from the sand surrounding it in the mold frame. Sand holds the EPS mold in place as molten metal is poured into it. As the foam evaporates, the required metal shape is left behind.

In lost-foam casting, foam patterns mimic the precise geometry of the finished metal object. The gating system has passages that direct molten metal into the mold and may be integrated into the foam pattern or attached (glued on) later. These passages enable precise designs and streamlined metal flow, resulting in castings that are accurate and effective.

Tightly bind the foam patterns and gating mechanisms to form the mold bundle module prior to casting. This assembly makes the casting process easier by ensuring precise component alignment, reducing mistakes, and facilitating reliable, consistent manufacture of complex metal parts.

An application of refractory dip paint follows the assembly of the mold bundle module. When this paint dries, it creates a protective ceramic coating that improves the mold's surface toughness, heat resistance, and capacity to handle the temperature and pressure of the molten metal.

Coat the mold bundle module, set it within a molding flask, and cover it in dry sand. This phase ensures accurate replication of the desired metal part by supporting the module's shape, keeping it in place during casting, and facilitating uniform sand compaction.

Sand may now flow into every nook and cranny of the mold bundle module thanks to vibrations imparted to the molding flask. Through careful sand compaction and the elimination of air spaces, this procedure enables the creation of a high-quality casting with exact measurements and fine details.

Carefully pour the molten metal into the mold, replacing the vaporized foam patterns. The metal solidifies to create the desired casting as it fills the spaces the foam left behind. As a result, the finished product closely resembles the planned form while minimizing flaws and blemishes. This technique supports complicated and complex shapes.

After the castings have cooled and set, clean the casting to get rid of any remaining sand, ceramic shells, and other impurities. To produce high-quality and aesthetically pleasing metal parts, this phase means that the final castings fulfill quality requirements, have smooth surfaces, and are ready for subsequent finishing procedures or assembly.

1. Significantly lower financial investment and reduce development time for prototype-making

2. Excels in producing castings with high dimensional accuracy, complex shapes and elaborate designs and broader weight range up to 500kgs.

3. Inherently avoids flash, the unwanted material accumulation on castings. The absence of a draft requirement ensures clean castings with impeccable dimensional accuracy.

4. It's simpler than many other casting methods, involving fewer steps which significantly lowers labor requirements and waste production.

5. It is possible to recycle used dry sand, which is in line with objectives for lowering emissions and using less energy. It can also reduce material waste and streamline manufacturing procedures, making it more effective and economical.

6. It can cast various kinds of metals such as stainless steel, aluminum alloys, steels, cast irons, nickel alloys into components for a wide range of industries including automobile, marine, military and agricultural fields, etc.

Qianhao New Material Foundry

Established in 2022.

40,000 SM under roof.

Equipped with more advanced lost foam casting and heat treatment automatic production line.

Annual capacity 30,000 Tons.

Foam Making

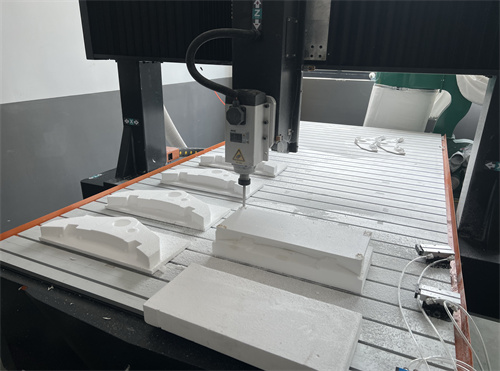

Foam Pattern Engraving (Prototype only)

Foam Pattern Making (For Serial Production)

Foam Pattern Smoothing

Foam Pattern Liquefying

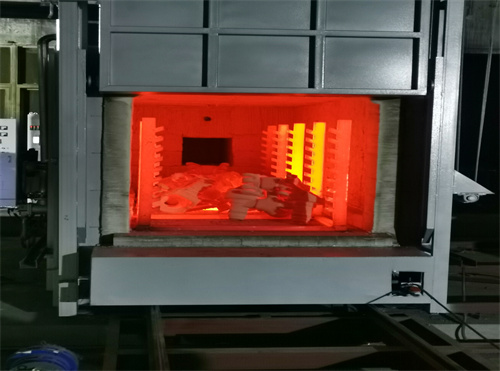

Heating and Drying

Coating

Gating System Gluing

Baking

Shell

Sand Filling

Sand Circulation Casting System

Negative Pressure Casting

Material: GS21Mn5

Weight: 175kgs

Material: A487 Gr4

Weight: 110kgs